-

N219Low-structure, super-abrasion furnace black

N219Low-structure, super-abrasion furnace black| Product

■N219 (ISAF-LS) low-structure, super-abrasion furnace black is a highly reinforcing type of carbonblack, and its structure is the lowest in the N200 series carbonblack. ■N219 is mainly used for tire tread, especially fits for off-road tires. Compared with the N220 carbonblack, it can improve the tensile strength, tear strength and elongation, and low heat, high flexibility, elongation and abrasion resistance were slightly lower... -

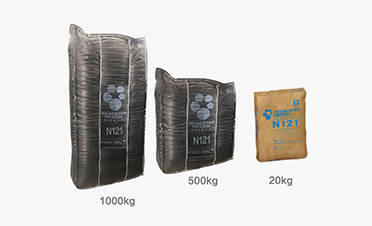

N121New technology high-structure super-wear furnace black

N121New technology high-structure super-wear furnace black| Product

■N121 new technology high-structure super-wear furnace black, is a new technology production of high-structure super-wear furnace black, with fine particles, high structure characteristics. ■N121 has the same general reinforcing property and dispersity in the compound as N220, but the wear resistance of the compound is better than N220. In... -

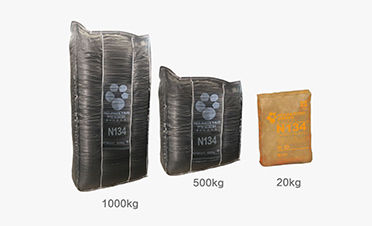

N134High-Structure Super-Wear Furnace Black

N134High-Structure Super-Wear Furnace Black| Product

■N134 has the best wear resistance and is easier to disperse than N110. Its Iodine absorption value is higher than N121 and close to N110. DBP absorption value is close to N121. ■N134 is mainly used in truck, bus and high performance passenger car tire tread compounds。 ■Packing Specifications:Paper-plastic compound bag: 20kg / bag; plastic woven FIBC: 500kg / bag, 1000kg / bag;Can be packaged according to user sp... -

N110Super abrasion carbon black

N110Super abrasion carbon black| Product

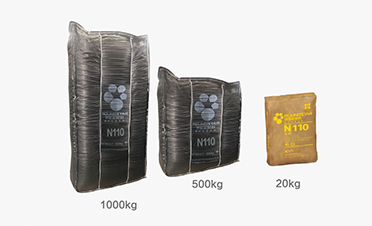

■N110 super wear-resistant furnace black is one of rubber carbon black with the smallest particle size, the highest reinforcing performance and the best wear-resistant performance ■N110 is mainly used for off-road tires and truck tire treads, bridge rubber pads, conveyor belts and other rubber products requiring excellent wear resistance. ■Packing Specifications:Paper-plastic compound bag: 20kg / bag; plastic woven...

Quality Assurance

Technical Index

Laboratory

The laboratory is equipped with 15 professional testing rooms such as element analysis room, strength testing room and physical analysis room. It has advanced testing equipment in the industry, including low-temperature nitrogen adsorption tester, automatic titration oil absorption meter, atomic emission spectrometer, single carbon black particle There are more than 50 testing and analysis instruments such as strength testers and electronic tensile machines. The laboratory has established a relatively complete test method for carbon black product inspection items in the industry in accordance with ASTM or national standards.

Oil absorption value tester, color strength tester, polycyclic aromatic hydrocarbon tester, weighing balance, solution preparation instrument, flat vulcanization tester, oil absorption value manual tester, drying box, nitrogen adsorption tester, heavy metal tester, compressor, Mooney Viscometer, Vibrating Screen, Toluene Transmittance Tester, Tensile Strength Tester, Sulfur Change Tester, Rubber Mixer, Particle Hardness Tester, Washed Screen Residue Tester